Packaging & Pharma Equipments

Automation Technologies, Bangalore

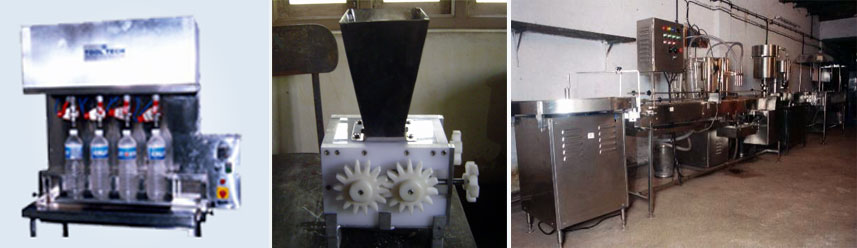

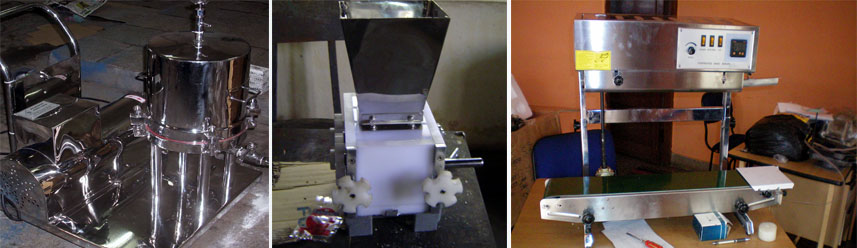

Automation Technologies manufacture and supply packaging and pharma customized equipments, sparkler / zero holdup filter press, multimill, pharmaceutical machineries, capsule filling machines, bottling lines, vibro sifters, auger filling machines to meet our customer's demand.

Packaging Machines & Pharmaceutical Equipments, Automation Technologies, Bengaluru Unit

Packaging Machines

Automation Technologies offer a wide range of pouch packing machines, these pouch packing machines are fabricated using high grade raw material and are known for high performance, efficiency, ease of use and durability. Available in standard specifications, our pouch packing machine is highly acclaimed for its features of smooth operations, optimum performance, low maintenance and long service life. Pouch packing machine to pack powders, granules, liquids in consumer pouches. Packing range -0 - 250gms, 250 - 500 gms, 500 - 1000gm.

Packaging Machines & Pharmaceutical Equipments, Automation Technologies, Bengaluru Unit

Pharmaceutical Equipments

Automation Technologies' horizontal filter press is a sparkler type and consist of SS shell & top cover using bolts to give pressure tight enclosure. The filter cartridge assembly inside the shell consists of several horizontally arranged disc type filter plates with perforated supporting screens, filter media & interlocking cups. The entire assembly complete with pump & piping connection is mounted on a suitable SS. Trolley Standard flow type: The impure liquid to be filtered is fed to the filter shell by pump. It arrives on top of each plate through opening on the sides of plates. As liquid pressure increases, the filter media (paper / fabric) holds back the impurities & allows the crystal clear filtrate to pass through the central channel (formed by interlocking cups) which takes the filtrate to the outlet of filter. This filter most commonly used to obtain clear liquid. However if required, the cake formed between the plates can be obtained. Filtration is continued until its rate becomes very slow due to increased cake resistance. Salient features: Manufactured in SS 304, SS 316, SS 316l MO CMS, SS jacket can be provided for hot filtration. Gives crystal clear filtration by filtering particles up to 1 micron size. Scavenger arrangement to remove all the liquid. Cake can be dried either by compressed air or by insert gas, steam. Filtration rates from 600 ltrs/hr. to 30000 ltrs/hr possible depending on the models.

Packaging Machines & Pharmaceutical Equipments

Packaging Machines & Pharmaceutical Equipments, Automation Technologies, Bengaluru Unit